Agricultural machinery bearings play a significant role in enhancing overall efficiency and reducing fuel consumption through various mechanisms:

Reduced Friction: Bearings serve as critical components in agricultural machinery, tasked with minimizing frictional resistance between moving parts. This friction arises during the interaction of surfaces within the machinery, leading to energy losses in the form of heat and mechanical resistance. By integrating high-quality bearings with advanced materials and precision engineering, agricultural machinery manufacturers can significantly mitigate frictional losses. For instance, bearings incorporating ceramic or polymer materials exhibit lower coefficients of friction compared to traditional steel bearings. Moreover, advanced surface treatments and lubrication techniques further reduce friction, optimizing energy efficiency and ultimately lowering fuel consumption.

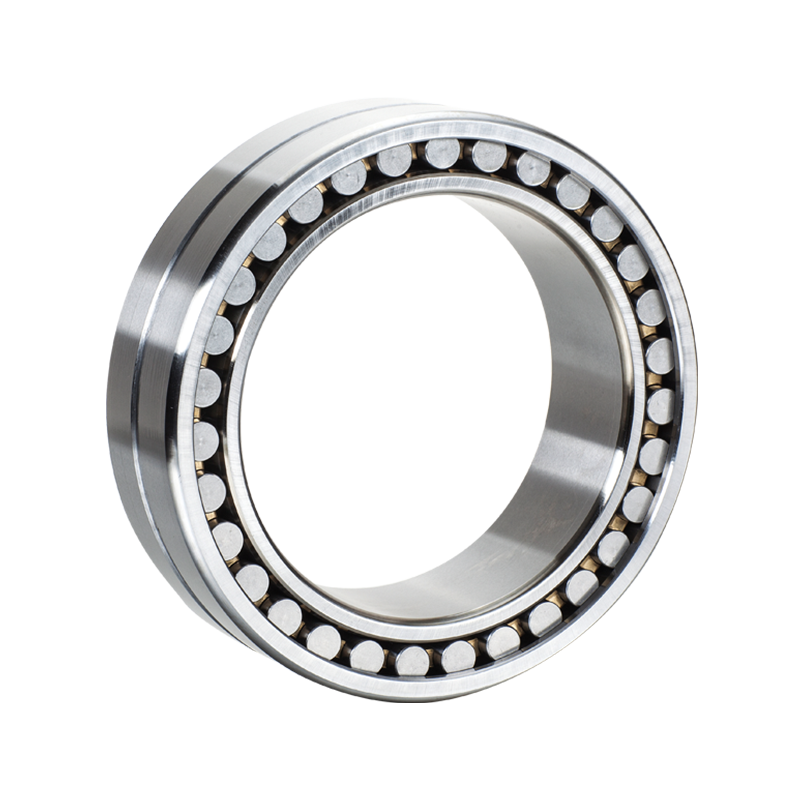

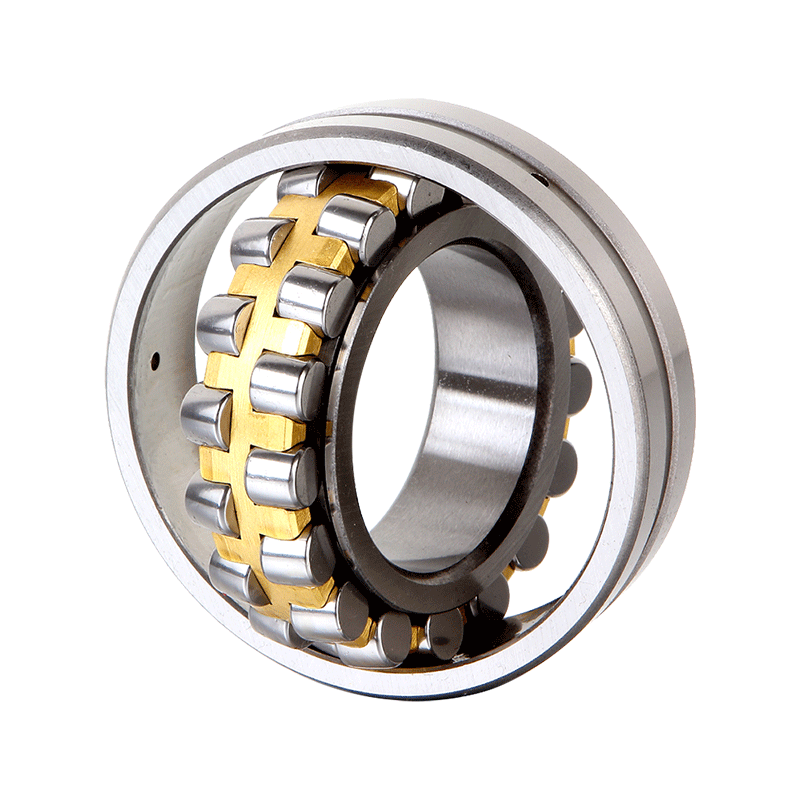

Smooth Operation: Agricultural machinery relies on the smooth and continuous movement of various components to perform tasks efficiently. Bearings facilitate this by providing support and guidance for rotating or linear motion elements such as shafts, gears, and wheels. Smooth operation is crucial for minimizing energy losses associated with vibrations, impacts, and irregular movements. Bearings with advanced designs, such as self-aligning or precision-engineered variants, ensure that components move with minimal resistance and without unnecessary strain. This seamless operation not only enhances overall machinery performance but also contributes to fuel efficiency by reducing energy wastage during operation.

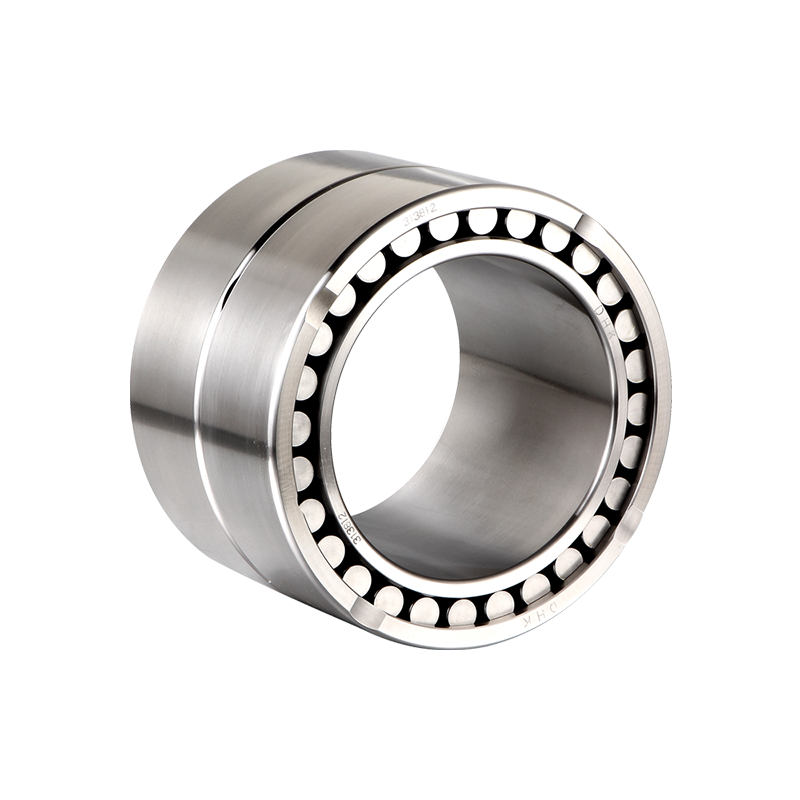

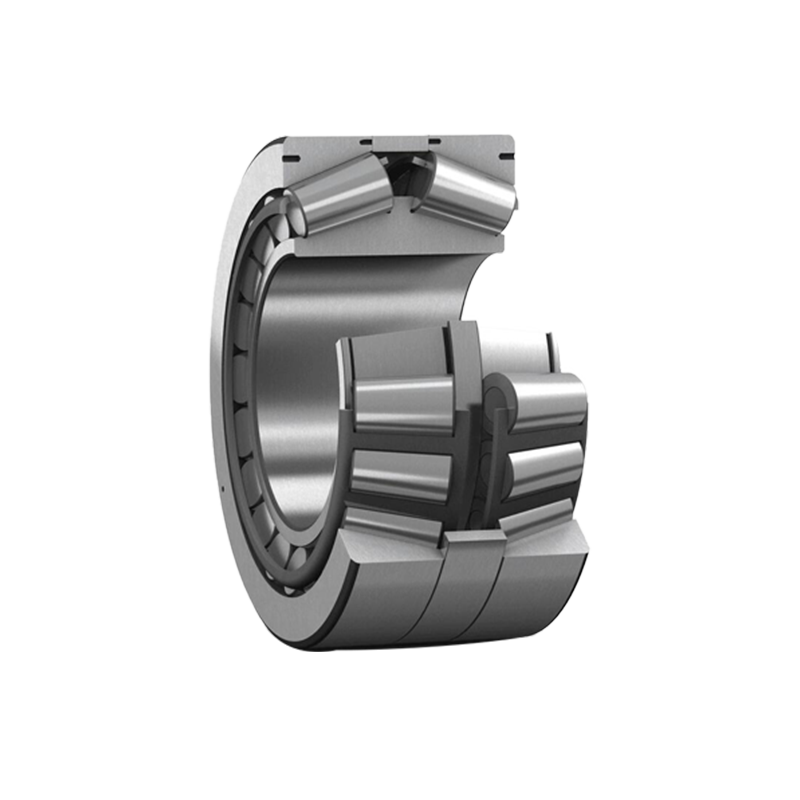

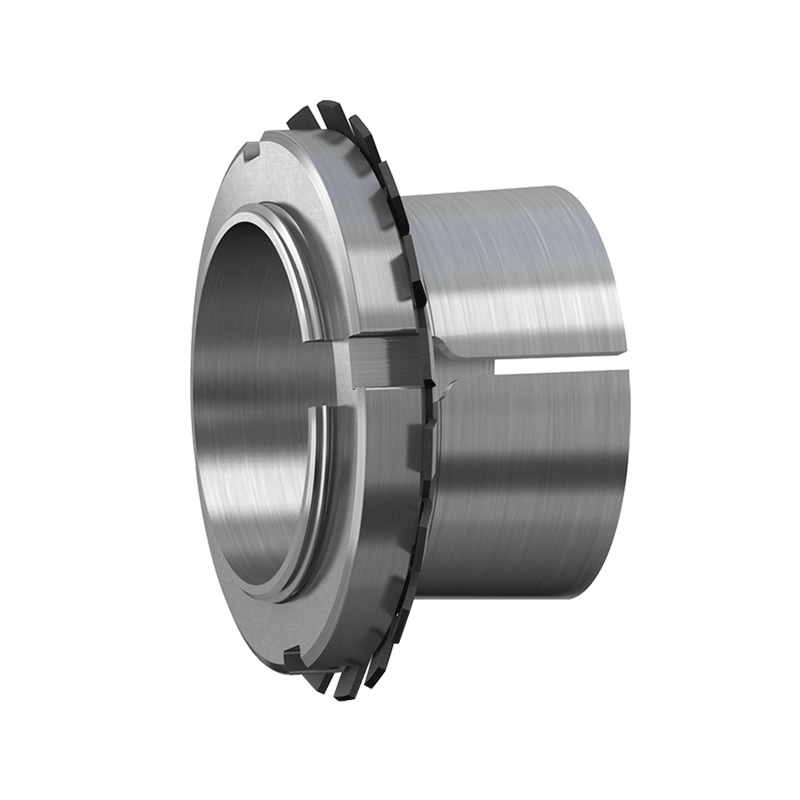

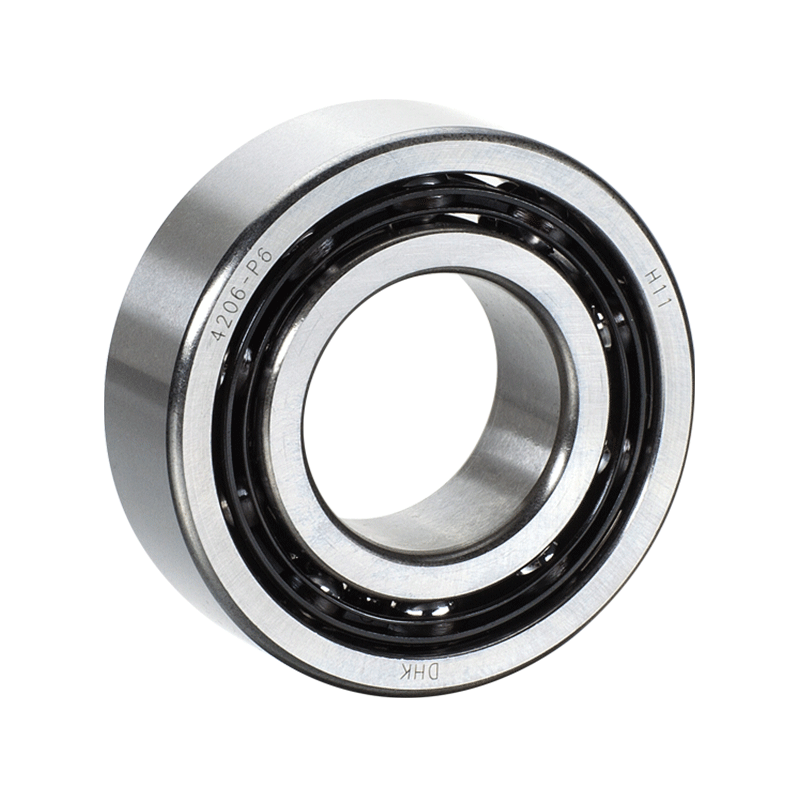

Optimized Power Transmission: Efficient power transmission is essential for maximizing the performance and minimizing the energy consumption of agricultural machinery. Bearings play a pivotal role in this process by facilitating the smooth and reliable transfer of power from the engine or motor to various operational components. By supporting rotating shafts, gears, and pulleys, bearings ensure that power is transmitted without significant losses due to slippage or mechanical inefficiencies. Advanced bearing technologies, such as angular contact or tapered roller bearings, are specifically designed to handle high loads and transmit power with minimal friction. This optimized power transmission not only enhances machinery efficiency but also directly impacts fuel consumption by maximizing the utilization of available energy resources.

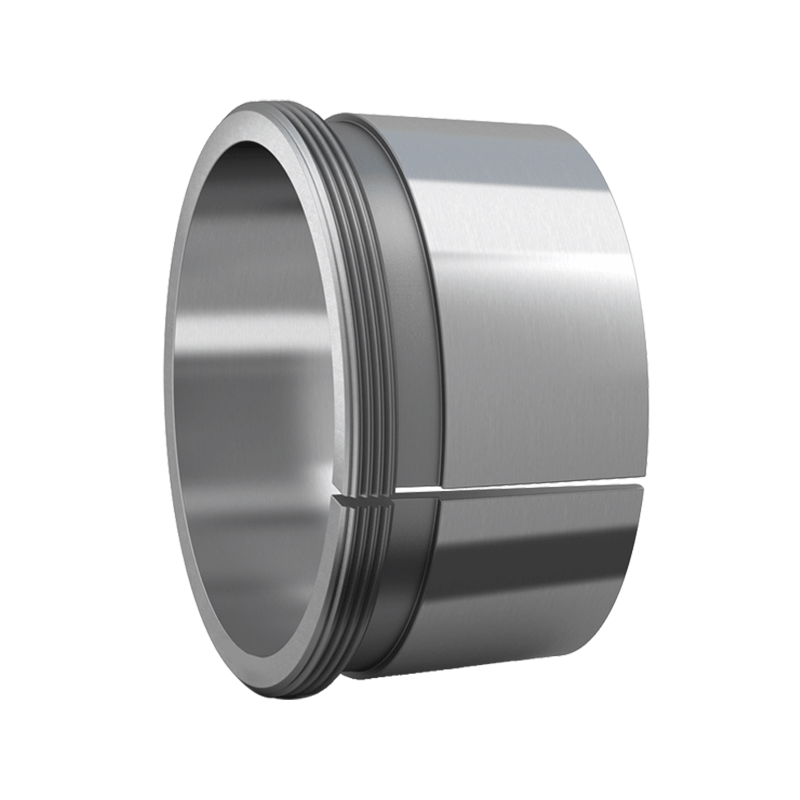

Precision and Alignment: Proper alignment and precise positioning of machine components are crucial for minimizing energy losses and optimizing operational efficiency. Bearings play a fundamental role in maintaining accurate alignment and positioning of shafts, gears, and other moving parts within agricultural machinery. By providing support and guidance for these components, bearings reduce frictional losses associated with misalignment and ensure consistent performance over time. Precision-engineered bearings, coupled with advanced mounting techniques and alignment procedures, contribute to minimizing wear and tear on mating surfaces, thus enhancing efficiency and reducing fuel consumption.

Reduced Downtime: Downtime resulting from machinery failures or maintenance activities can significantly impact productivity and fuel efficiency in agricultural operations. Bearings that exhibit high reliability and durability are essential for minimizing downtime and maximizing machinery uptime. Manufacturers utilize advanced materials, coatings, and sealing technologies to enhance the performance and longevity of bearings under harsh operating conditions. By incorporating bearings with extended service life and robust performance characteristics, agricultural machinery operators can reduce the frequency of maintenance interventions and unplanned downtime. This increased reliability translates into higher productivity and reduced fuel consumption by ensuring that machinery remains operational for longer periods.

Radial Insert Ball Bearings Without Eccentric Locking Collar

Radial Insert Ball Bearings Without Eccentric Locking Collar

English

English Deutsch

Deutsch