Full complement cylindrical roller bearings are non-separable bearings, exception series NJ23 VH.

This kind of bearings features a much higher internal friction due to them without cage. So the speed ratings are limited.

Full complement cylindrical roller bearings are mainly produced in single row and double row designs.

Un-sealed single row and double row bearings are frequently used in gearbox, sealed double row bearings are frequently used in hoisting mechanism.

Additional to the standard products range of single row and double row full complement cylindrical roller bearings, DHK can produce other full complement bearings according to individual customer specifications or special bearings upon request.

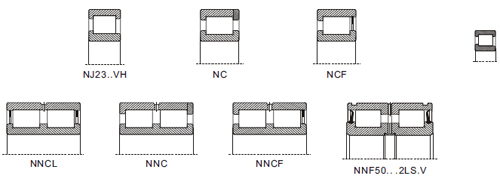

The most important basic types are shown on the below.

Single row bearings

Series NJ23...VH these bearings feature two integral flanges on their outer ring and one integral flange on their inner ring, thus there are able to accommodate minor thrust force in one direction only. Bearings of this series are self-retaining roller assemblies, which enable the removal of inner rings without loss of roller retention in the outer rings.

Series NC...: These bearings feature two integral flanges in their inner ring and an outer ring with one integral flange one side and one loose rib on its opposite side. Thus they are able to be used as locating bearings and accommodate minor axial force in both directions.

Series NCF...These bearings feature two integral flanges on the inner ring and an outer ring with one integral flange on one side and a retaining ring which sitting in circumferential groove at the opposite side. Thus these bearings are able to accommodate minor axial force in one direction only.

Double row bearings

Series NNCL...: This type double row cylindrical roller bearings have an inner ring with three integral flanges and a plain outer ring. The outer ring has two retaining rings which sitting in circumferential groove on both sides of the raceway diameter to retain the outer ring and bearing assembly. Thus these bearings could not accommodate any axial force.

Series NNC... This type bearing has three integral flanges on their inner ring and an outer ring with one integral flanges on one side and a loose rib on the opposite side. Thus these bearings are able accommodate minor axial forced in both directions and can be used as locating bearing.

Series NNCF... This type bearing feature three integral flanges on the inner ring and an outer ring with one integral flanges at one side and a retaining ring which sitting in circumferential groove at the opposite side.

Thus these bearing are able to accommodate minor axial force in on direction only.

Series NNF50...2LS.V: Bearings of this series feature an outer ring with a center integral flange and two half inner ring with two integral flanges on each half .Two half inner rings are connected by a connecting ring which also retains the outer ring and bearing assembly. These bearings also feature lubrication grooves and hole both on outer ring and inner ring and two snap grooves on outer diameter.

These bearings are supplied with two contacting seals (suffix .2LS) and pre-greased. However, if need supplied with snap rings (suffix.2NR), please make clear before release the order.

These series bearings have an outer ring with l mm less than the width of inner ring, several same bearings simply mounted on one shaft and there are a space between outer rings face, and this enable the different outer rings have different speed, this feature make it performance well when it used as pulley bearings.