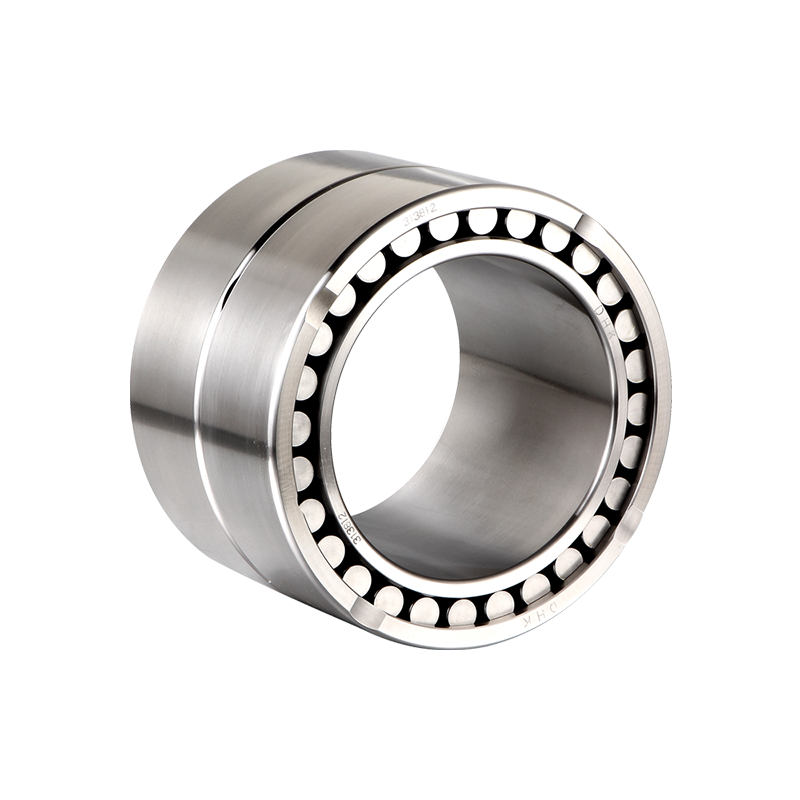

Load Capacity: Agricultural machinery operates in diverse conditions, encountering a wide range of loads depending on the task at hand. From lightweight operations such as seeding to heavy-duty tasks like tilling or harvesting, the load capacity of bearings plays a critical role in ensuring reliable performance and longevity. Bearings subjected to loads beyond their capacity risk premature failure, leading to costly downtime and repairs. Therefore, meticulous consideration of the anticipated loads and selection of bearings with appropriate load ratings are paramount. Engineers and operators must analyze factors such as the weight of the equipment, the force exerted during operation, and potential dynamic loads to accurately determine the required load capacity for bearings in agricultural applications.

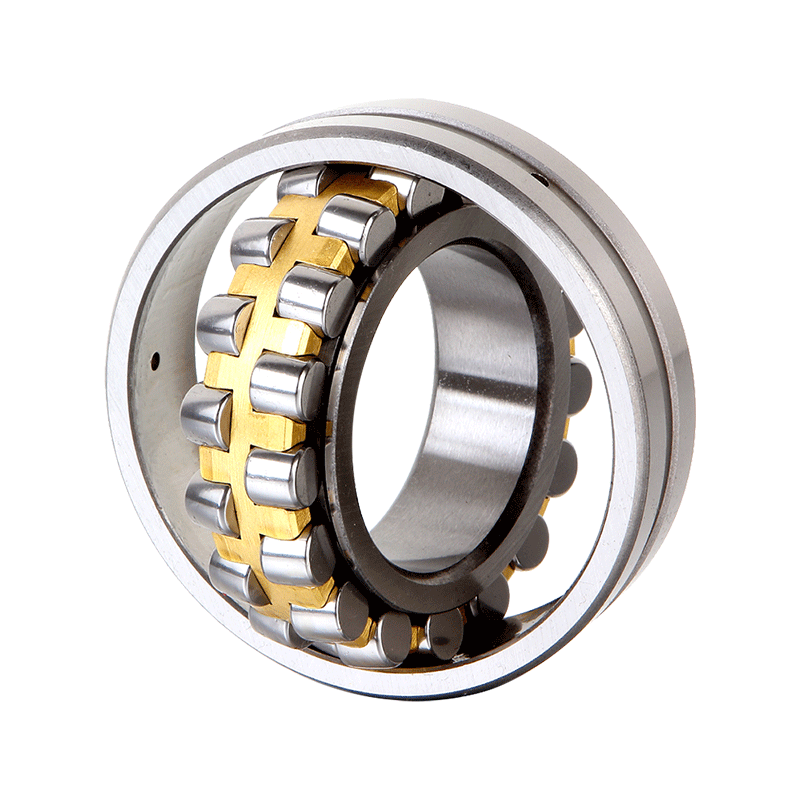

Rotational Speed: Agricultural machinery operates at varying rotational speeds depending on the equipment type and the specific task being performed. For instance, high-speed operations are common in harvesting equipment and grain conveyors, where rapid processing is essential for efficiency. Bearings selected for such applications must be capable of withstanding the associated rotational speeds without compromising performance or safety. Factors such as bearing material, lubrication, and design play crucial roles in ensuring adequate heat dissipation, minimizing friction, and maintaining structural integrity under high-speed conditions.

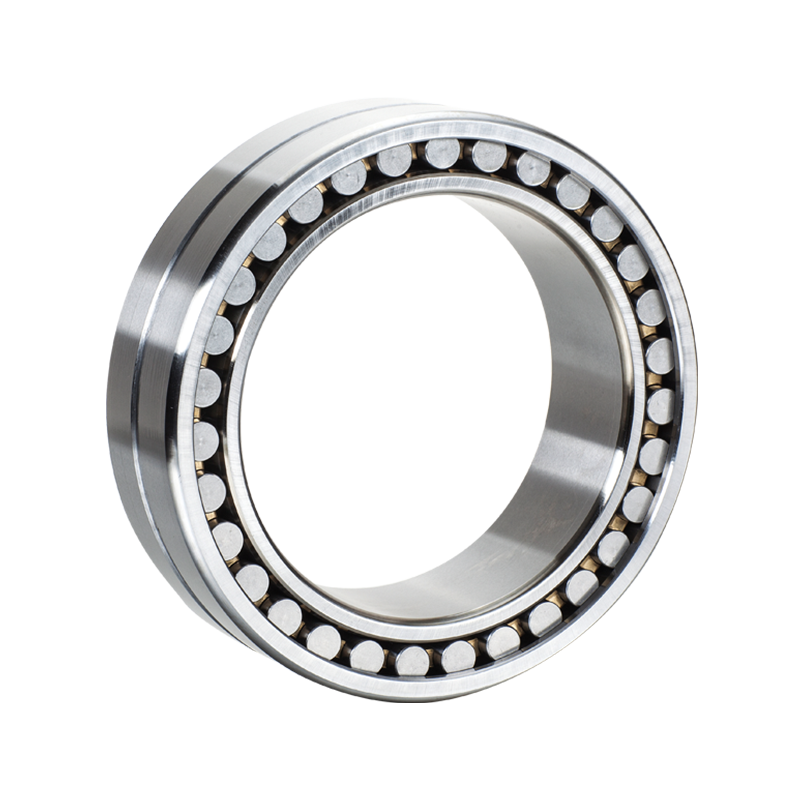

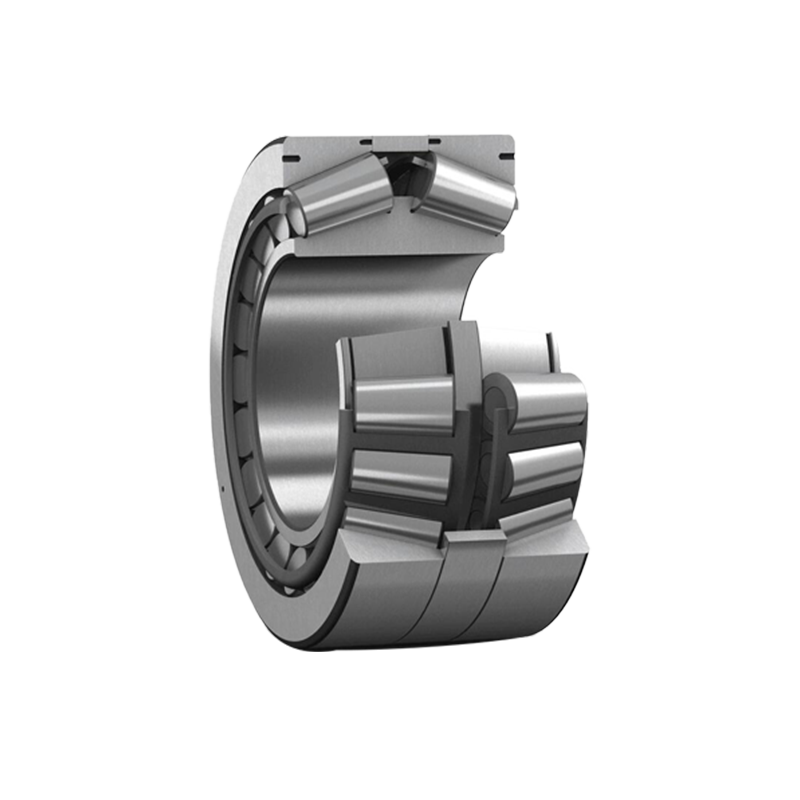

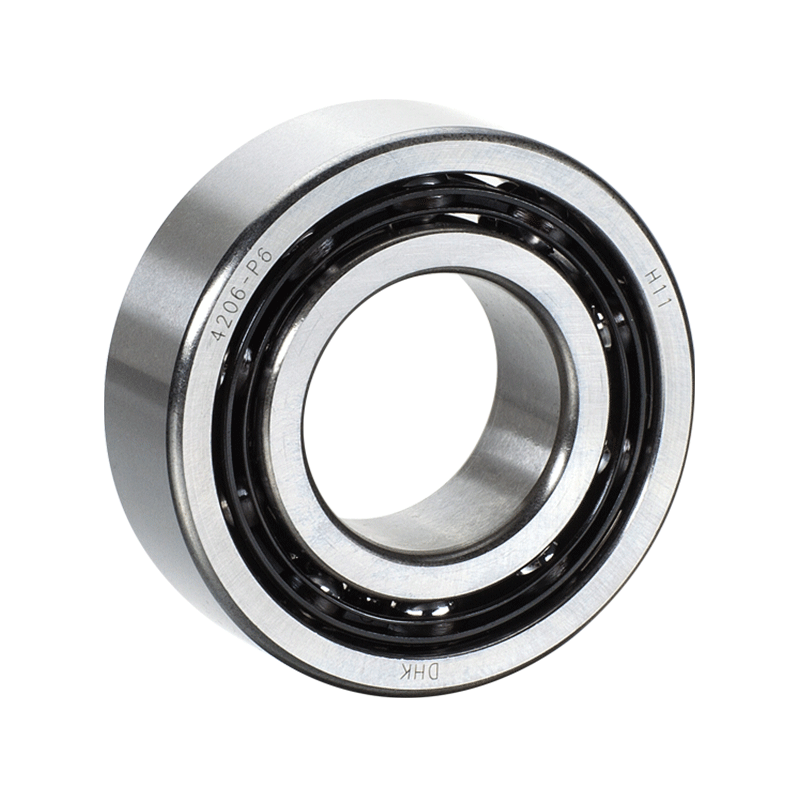

Combined Loads: In many agricultural applications, bearings are subjected to both radial and axial loads simultaneously, often referred to as combined loads. For example, in tillage equipment, bearings may experience radial loads from the weight of the implement and axial loads due to the forces exerted during tilling. It is imperative to select bearings capable of accommodating these combined loads efficiently to prevent premature fatigue and failure. Bearings with superior load-carrying capabilities and optimized internal geometries are preferred for applications where combined loads are prevalent.

Environmental Conditions: Agricultural machinery operates in harsh and unpredictable environments characterized by exposure to dust, moisture, chemicals, and other contaminants. These environmental factors pose significant challenges to bearing performance and longevity, potentially leading to accelerated wear, corrosion, and premature failure. Therefore, bearings selected for agricultural applications must be designed to withstand such adverse conditions while maintaining reliable operation. Sealed or shielded bearings, equipped with protective barriers to prevent ingress of contaminants and moisture, are commonly employed in agricultural machinery to enhance durability and reliability. Specialized coatings, surface treatments, and materials resistant to corrosion and abrasive wear may be utilized to further enhance the performance of bearings in challenging agricultural environments.

Maintenance Requirements: Agricultural operations often span large areas and involve intensive usage of machinery, making regular maintenance and servicing challenging, especially in remote or demanding environments. Therefore, the selection of bearings for agricultural machinery should take into account the maintenance requirements to minimize downtime and operational disruptions. Bearings that require minimal maintenance, such as sealed or pre-lubricated units, are favored for agricultural applications, as they reduce the need for frequent relubrication and inspection. Self-lubricating bearings equipped with integrated lubrication systems or solid lubricants offer extended service intervals and enhanced reliability, further streamlining maintenance efforts.

Radial Insert Ball Bearings Without Eccentric Locking Collar

English

English Deutsch

Deutsch